- Courses

- GS Full Course 1 Year

- GS Full Course 2 Year

- GS Full Course 3 Year

- GS Full Course Till Selection

- Online Program

- GS Recorded Course

- NCERT (Recorded 500+ Hours)

- Polity Recorded Course

- Geography Recorded Course

- Economy Recorded Course

- AMAC Recorded Course

- Modern India, Post Independence & World History

- Environment Recoded Course

- Governance Recoded Course

- Science & Tech. Recoded Course

- International Relations and Internal Security Recorded Course

- Disaster Management Module Course

- Ethics Recoded Course

- Essay Recoded Course

- Current Affairs Recoded Course

- CSAT

- 5 LAYERED ARJUNA Mentorship

- Public Administration Optional

- ABOUT US

- OUR TOPPERS

- TEST SERIES

- FREE STUDY MATERIAL

- VIDEOS

- CONTACT US

Miniature Laser Grown on Silicon Chip

Miniature Laser Grown on Silicon Chip

17-04-2025

- Recently, Scientists from the US and Europe have successfully grown miniature lasers directly on silicon wafers.

- This marks a major progress in silicon photonics, a technology that uses light (photons) instead of electricity (electrons) to transmit information on chips.

What is Silicon Photonics?

- Silicon photonics uses photons to carry data, replacing electrons used in traditional chips.

- This is about using light instead of electricity inside computer chips.

- Traditional chips work by moving electrons through circuits.

- The new method uses photons, or light particles, to carry information — this is called silicon photonics.

- Advantages of photons over electrons:

- Travel faster

- Provide higher data bandwidth

- Cause lower energy losses

- Applications:

- Already used in data centres and optical sensors

- Has potential in quantum computing and high-speed data transmission

The Main Challenge in Photonic Chips

- A laser is required as a light source on the chip.

- Traditionally, lasers are manufactured separately and then attached to the chip.

- This method causes:

- Slower performance

- Manufacturing mismatches

- Higher cost

- Integrating the laser directly on the chip has been a long-standing technological problem.

The Progress

- Researchers grew lasers directly on a silicon chip using a scalable, cost-effective method.

- The process was conducted in a standard CMOS (Complementary Metal-Oxide-Semiconductor) facility.

- CMOS is widely used in current semiconductor manufacturing.

- This makes the technique compatible with existing manufacturing processes.

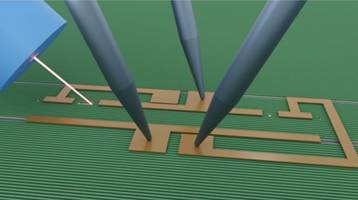

Components of a Photonic Chip

A typical photonic silicon chip consists of four main components:

- Laser (light source) – generates photons.

- Waveguides – guide photons, like wires guide electrons.

- Modulators – encode or decode data by altering light properties like intensity, phase, or wavelength.

- Photodetectors – convert light signals into electrical signals.

How Lasers Work (Stimulated Emission)

- Laser stands for Light Amplification by Stimulated Emission of Radiation.

- In this process:

- A photon causes an excited electron to release energy and drop to a lower level.

- This releases another identical photon.

- The chain reaction creates a coherent light beam – the laser.

Why Silicon Alone Doesn’t Work

- Silicon has an indirect bandgap, so it is not efficient at emitting light.

- Materials like Gallium Arsenide (GaAs) have a direct bandgap and can emit light efficiently.

- Problem: GaAs and silicon have different crystal structures, causing defects when grown together.

- These defects make the laser less efficient by turning light energy into heat.

The Solution – 'Trench Design'

- Inspired by a 2007 AmberWave Systems study.

- Researchers:

- Created deep trenches in the silicon wafer.

- Filled trenches with silicon dioxide (an insulator).

- Deposited GaAs at the trench bottom so defects remained trapped and didn’t affect the laser.

- Grew defect-free GaAs above the trench.

- Added three thin layers of Indium Gallium Arsenide (InGaAs) to act as the laser.

- InGaAs is GaAs with 20% gallium replaced with indium for better light emission.

- Covered with Indium Gallium Phosphide for protection.

- Electrical contacts were added to power the laser.

Key Data and Results

- 300 functional lasers were grown on a single 300-mm silicon wafer.

- 300 mm is the industry-standard wafer size.

- Laser emitted light at a wavelength of 1,020 nm.

- Suitable for short-distance communication between chips.

- Threshold current to power the laser: 5 mA (same as an LED in a computer mouse).

- Laser output: approximately 1 milliwatt (mW).

- Continuous operation:

- Worked for 500 hours at room temperature (25°C).

- Efficiency dropped at 55°C.

- Other optical chips have worked up to 120°C, so further stability improvements are needed.

Significance of the Breakthrough

- First monolithic laser diode successfully grown on a 300-mm silicon wafer.

- This approach:

- Solves the long-standing issue of integrating lasers with chips.

- Can lead to faster computing, lower energy consumption, and reduced costs.

- Especially beneficial for data centres, AI systems, and green computing.

- The process is scalable, efficient, and can be used with existing chip-making facilities.