- Courses

- GS Full Course 1 Year

- GS Full Course 2 Year

- GS Full Course 3 Year

- GS Full Course Till Selection

- MEP (Mains Enrichment Programme) Data, Facts

- Essay Target – 150+ Marks

- Online Program

- GS Recorded Course

- NCERT- First Ladder

- Polity

- Geography

- Economy

- Ancient, Medieval and Art & Culture AMAC

- Modern India, Post Independence & World History

- Environment

- Governance

- Science & Technology

- International Relations and Internal Security

- Disaster Management

- Ethics

- Current Affairs

- Indian Society and Social Issue

- CSAT

- 5 LAYERED ARJUNA Mentorship

- Public Administration Optional

- ABOUT US

- OUR TOPPERS

- TEST SERIES

- FREE STUDY MATERIAL

- VIDEOS

- CONTACT US

India’s Opportunity in the $100 Billion Global Tools Market

India’s Opportunity in the $100 Billion Global Tools Market

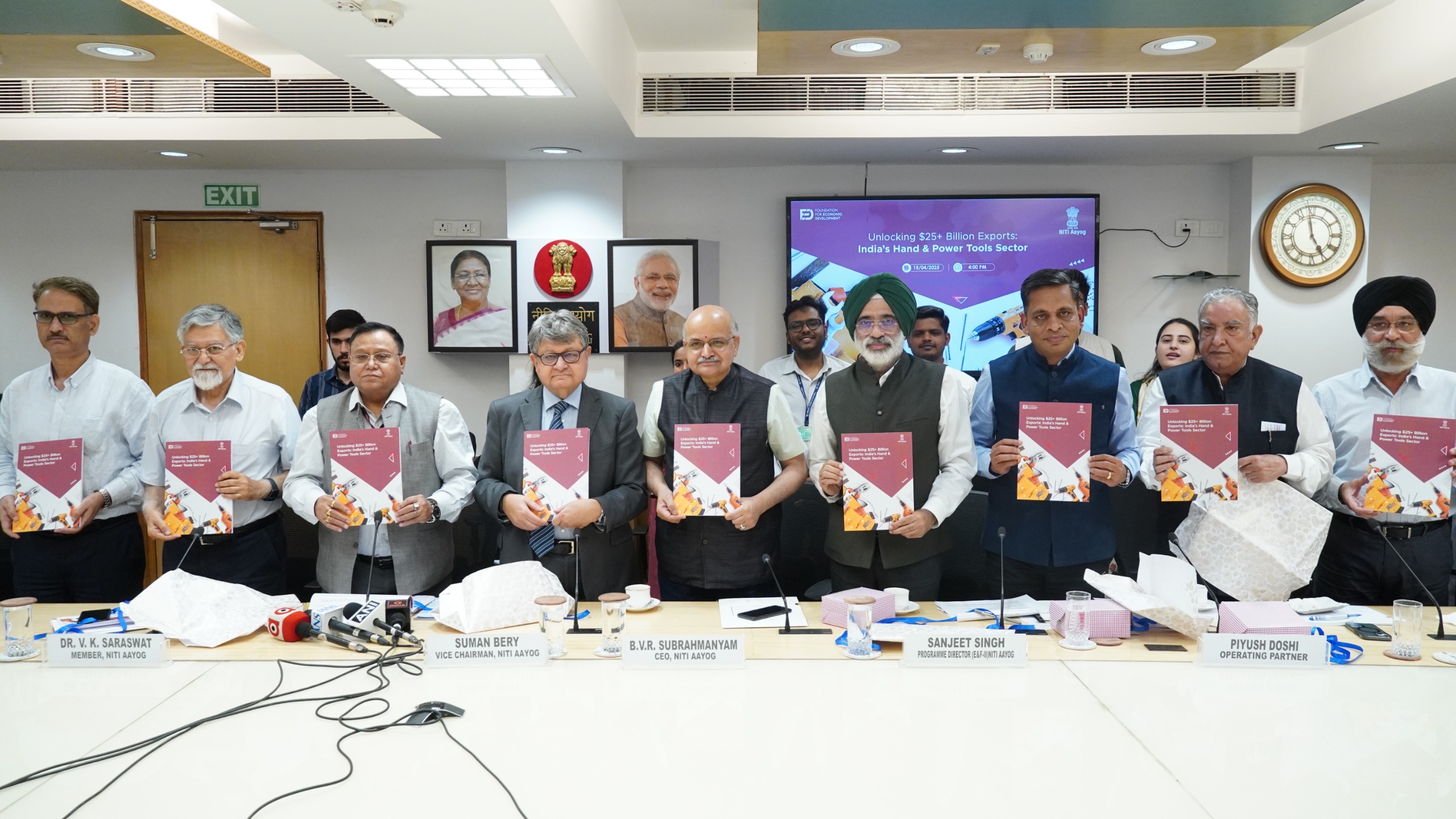

Based on NITI Aayog’s April 2025 Report: “Unlocking $25+ Billion Exports: India’s Hand & Power Tools Sector”

Report Background

- The report was published by NITI Aayog, the central government’s policy think tank.

- It was prepared in collaboration with the Foundation of Economic Development.

- It assessed 18 Indian states and gives a strategic roadmap to scale up India’s tools exports.

Global Market & China’s Dominance

- The global tools market was worth $100 billion in 2022, projected to grow to $190 billion by 2035.

- China holds nearly 50% share, due to large-scale, cost-efficient production and strong global supply chains.

- But now, rising tariffs and increasing costs in China have created an opportunity for India.

India’s Current Status

- India currently exports:

- $600 million in hand tools

- $425 million in power tools

- This is just a tiny share of the global trade, but it shows untapped potential.

What Are Hand and Power Tools?

- These are tools used in drilling, cutting, fastening, etc.

- They are essential across industries like infrastructure, automotive, manufacturing, and household use.

NITI Aayog’s Vision: $25 Billion by 2035

- India can build a $25 billion export-oriented tools industry by 2035.

- To achieve this, bold policy reforms, world-class manufacturing clusters, and public-private collaboration are needed.

Key Recommendations in the Report

- Build globally competitive tool manufacturing clusters.

- Reduce structural cost disadvantages (like energy, logistics, and compliance costs).

- Provide targeted government support, especially for small and medium enterprises (SMEs).

India’s Strengths

- India has low-cost labour, a growing manufacturing base, and strategic trade access.

- These can be used to bridge the 14–17% cost gap with global competitors.

Economic & Social Impact

- NITI Aayog says tools manufacturing can drive inclusive growth, especially in states like Punjab and Maharashtra.

- It can also strengthen MSMEs, increase employment, and reduce dependence on imports.

- NITI Aayog believes India is at a turning point and can become a global leader in the tools industry with the right strategy and reforms.

|

Hand Tools |

Power Tools |

Raw Materials Required |

Infrastructure Required |

|

Screwdrivers |

Electric drills |

Steel and Alloys – for strength and durability |

Forging & Casting Units – shaping metals into rough tool forms |

|

Hammers |

Angle grinders |

Aluminum – used in lightweight power tool bodies and housings |

CNC Machining & Precision Tooling – accurate cutting and shaping |

|

Spanners/Wrenches |

Electric saws |

Plastics and Polymers – for handles, outer casings, switches, insulation |

Heat Treatment Facilities – strengthen metal parts |

|

Pliers |

Nail guns |

Copper and Wires – for electric motors, coils, internal wiring |

Plastic Molding Units – for plastic parts like housings and switches |

|

Saws (manual) |

Heat guns |

Rubber and Grips – for safe, anti-slip handles |

Motor Assembly Units – to build and test internal motors |

|

Chisels |

Power sanders |

Electronic Components – sensors, microcontrollers, switch circuits |

Electronics Assembly Lines – for circuits in smart tools |

|

Tape measures |

Welding machines |

Bearings, Screws, Springs, Small Fittings – for smooth movement and part assembly |

Surface Finishing Units – polishing, painting, chrome plating |

|

Quality Testing & Calibration Labs – check strength & performance |

|||

|

Packaging & Logistics Support – storage, transport, export |