- Courses

- GS Full Course 1 Year

- GS Full Course 2 Year

- GS Full Course 3 Year

- GS Full Course Till Selection

- Online Program

- GS Recorded Course

- NCERT (Recorded 500+ Hours)

- Polity Recorded Course

- Geography Recorded Course

- Economy Recorded Course

- AMAC Recorded Course

- Modern India, Post Independence & World History

- Environment Recoded Course

- Governance Recoded Course

- Science & Tech. Recoded Course

- International Relations and Internal Security Recorded Course

- Disaster Management Module Course

- Ethics Recoded Course

- Essay Recoded Course

- Current Affairs Recoded Course

- CSAT

- 5 LAYERED ARJUNA Mentorship

- Public Administration Optional

- ABOUT US

- OUR TOPPERS

- TEST SERIES

- FREE STUDY MATERIAL

- VIDEOS

- CONTACT US

Carbon Capture and Utilisation (CCU) Testbeds

Carbon Capture and Utilisation (CCU) Testbeds

20-05-2025

Why in News?

Recently, the Department of Science and Technology (DST) has launched a new initiative to reduce pollution from the cement industry on National Technology Day, 11th May 2015.

- It involves setting up five Carbon Capture and Utilisation (CCU) Testbeds in the cement sector to promote Green Cement.

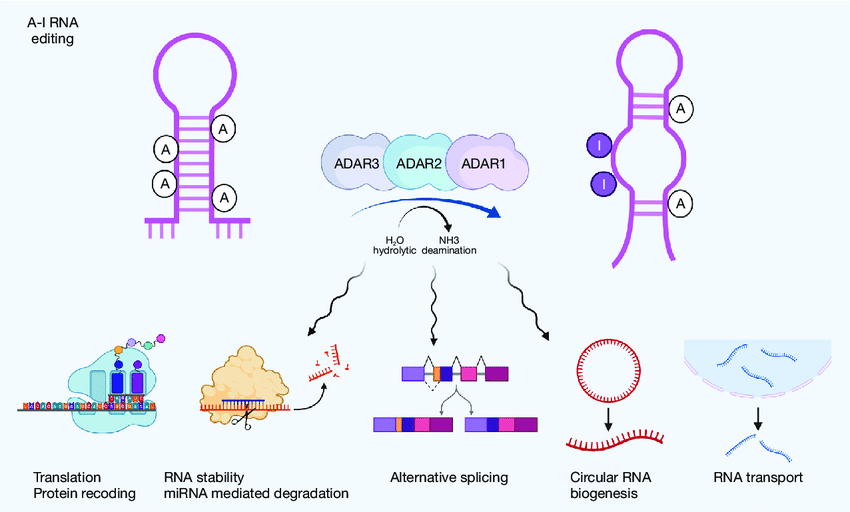

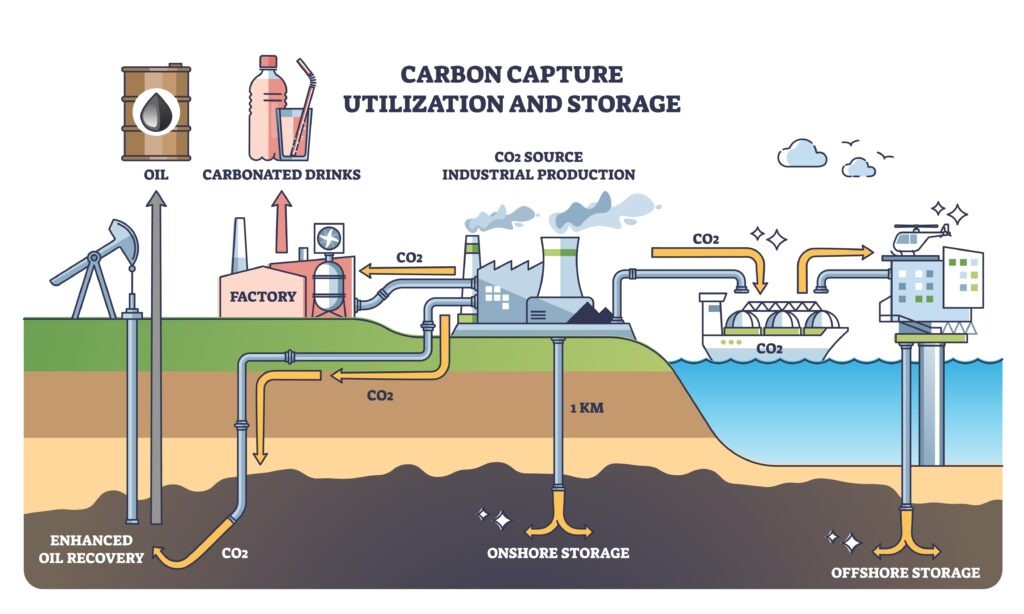

What is Carbon Capture and Utilisation (CCU)?

- About:

- CCU is a modern technology that captures CO₂ released during industrial processes.

- It is promoting the reuse of emitted CO2 .

- Uses:

- Synthetic fuels: CCU can be used to produce synthetic fuels like kerosene, which can be used in aviation or other sectors.

- Chemicals: CO2 can be converted into chemicals like urea, which is used in fertilizers.

- Building materials: CO2 can be used to manufacture concrete and cement, reducing the carbon footprint of these materials.

- Other products: CCU can also be used to create materials like carbon nanotubes and graphene, which have various applications in technology.

- Benefits of CCU:

- Reduced emissions: CCU helps to reduce CO2 emissions from industrial sources.

- Resource efficiency: CCU can reduce the reliance on fossil fuels and other resources.

- Economic growth: It can create new industries and jobs in the carbon capture and utilization sector.

- Environmental benefits: It can help to mitigate climate change and improve air quality.

What are the Importance of CCU?

- The CCU initiative is a significant step towards helping India to achieve its climate objectives.

- Achiveing net-zero carbon emissions by 2070.

- Fulfilling the Nationally Determined Contributions (NDCs) under the Paris Agreement.

- This initiative will contribute to creating new employment opportunities, fostering innovation, and building a cleaner, greener economy for future generations.

What is Green Cement?

- Green cement is a kind of cement that is better for the environment.

- It is made using a process that produces much less carbon dioxide (CO₂), which helps in controlling the pollution.

- Green cement uses waste leftovers from industries, like slag from blast furnaces and fly ash instead of using only new raw materials.

- The technology used to make green cement saves a lot of energy and releases much less CO₂ about 40% less compared to regular cement.

- Green cement also costs less to make and is cheaper to buy because it uses waste materials.

What are the Testbeds?

- A testbed is like a small project or experiment where new ideas and technologies are tested.

- These five testbeds will test different ways to capture carbon dioxide (CO₂) which is a major green house gas that causes global warming.

What will Each Testbed Do?

- Each testbed is trying a different method to reduce CO₂ from cement factories.

- Testbed 1 (JK Cement Ballabhgarh):

- It will capture two tonnes of CO₂ every day.

- The CO2 will turn into lightweight blocks (Concrete Block) and olefins (alkene used in making plastics).

- It uses a method called oxygen calcination.

- Testbed 2 (IIT Kanpur and JSW Cement):

- It will test CO₂ mineralisation.

- Mineralisation means turning CO₂ into solid materials like rocks or bricks.

- Testbed 3 (IIT Bombay and Dalmia Cement):

- It will use catalysts to capture CO₂ more efficiently. The catalyst will help the chemical reaction happen more quickly.

- Testbed 4 (CSIR-IIP, IIT Tirupati, IISc and JSW Cement):

- It will use vacuum swing adsorption.

- This is a method where CO₂ is pulled out of the air using a vacuum and special materials.

- Testbed 5 ( IIT Madras, BITS Pilani Goa and UltraTech Cement)

- It will work on new process ideas to lower carbon emissions at every step of cement production.

- Testbed 1 (JK Cement Ballabhgarh):

Why Focus on the Cement Sector?

- Carbon dioxide (CO₂) pollution from cement factories in India has increased almost four times since the year 2000.

- Cement production in India released about 177 million tonnes of CO₂ in the year 2023.

- This was around 6% of all CO₂ pollution from fossile fuel use and industries in India that year.

- India's cement industry alone caused 6% of the country’s industrial pollution and 11% of the world’s cement pollution in 2023.

How does Public-Private Partnership promote innovation in CCU?

- This CCU project is being done in a Public-Private Partnership (PPP) model.

- The top research institutions are working together with Major cement companies.

- This project will be supported by Government funding.

- This collaboration helps in sharing knowledge, testing new technologies in real-world conditions, and making them ready for large-scale use.

What are the Challenges Associated with CCU?

- High Costs: Implementing CCU technology requires significant investment, making it expensive for many industries to adopt.

- Technical Complexity: Capturing and converting CO₂ efficiently involves complex processes that need advanced technology and expertise.

- Energy Requirements: CCU processes can consume a lot of energy, which may reduce overall efficiency if not managed properly.

- Limited Infrastructure: There is a lack of widespread infrastructure to capture, transport, and utilize CO₂ on a large scale.

- Market Development: Products made from captured CO₂ are still emerging, and demand for these products is not yet strong enough to sustain large-scale CCU operations.

Way forward:

- Increase Research and Innovation: Support ongoing research to improve CCU technologies, making them more efficient and affordable.

- Government Incentives and Funding: Provide financial support, subsidies, and policy incentives to encourage industries to adopt CCU solutions.

- Capacity Building and Training: Train workers and managers to operate and maintain CCU technologies effectively.

- Develop Infrastructure: Build the necessary facilities for capturing, transporting, and utilizing CO₂ at a larger scale.

- Promote Market Creation: Encourage the use and demand of CO₂-based products through awareness campaigns and industry partnerships to ensure sustainability of CCU initiatives.

Official Secrets Act, 1923; and Section 152 of Bharatiya Nyaya Sanhita(BNS)

Official Secrets Act, 1923; and Section 152 of Bharatiya Nyaya Sanhita(BNS)