- Courses

- GS Full Course 1 Year

- GS Full Course 2 Year

- GS Full Course 3 Year

- GS Full Course Till Selection

- Answer Alpha: Mains 2025 Mentorship

- MEP (Mains Enrichment Programme) Data, Facts

- Essay Target – 150+ Marks

- Online Program

- GS Recorded Course

- Polity

- Geography

- Economy

- Ancient, Medieval and Art & Culture AMAC

- Modern India, Post Independence & World History

- Environment

- Governance

- Science & Technology

- International Relations and Internal Security

- Disaster Management

- Ethics

- NCERT Current Affairs

- Indian Society and Social Issue

- NCERT- Science and Technology

- NCERT - Geography

- NCERT - Ancient History

- NCERT- World History

- NCERT Modern History

- CSAT

- 5 LAYERED ARJUNA Mentorship

- Public Administration Optional

- ABOUT US

- OUR TOPPERS

- TEST SERIES

- FREE STUDY MATERIAL

- VIDEOS

- CONTACT US

Electrolysers: A Key Component in Green Hydrogen Production

Electrolysers: A Key Component in Green Hydrogen Production

06-05-2024

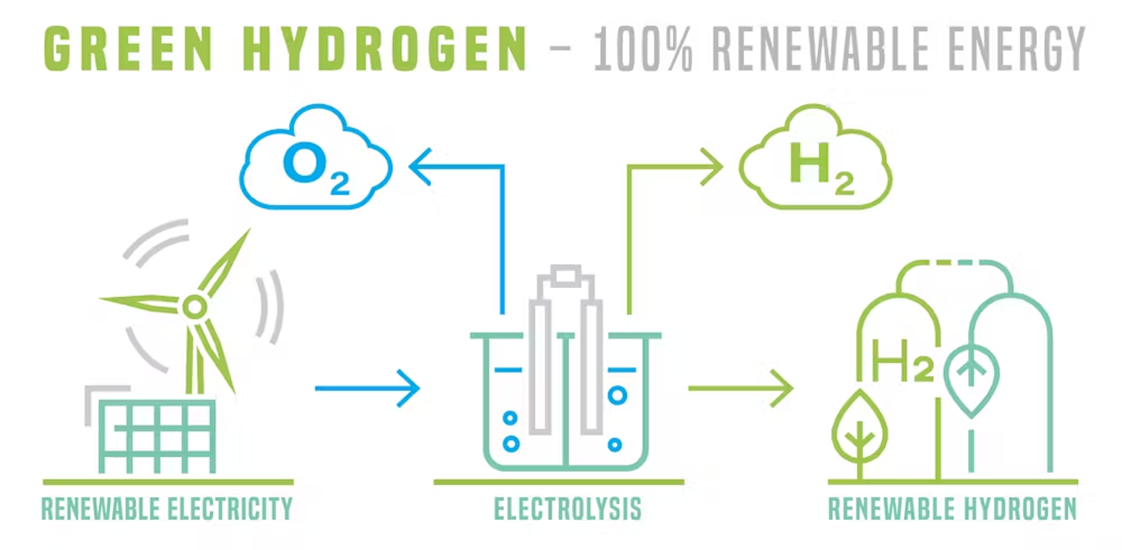

- Electrolyzers are devices that play an important role in generating green hydrogen, a clean and sustainable alternative to fossil fuels.

- Using electricity, electrolyzers split water molecules into hydrogen and oxygen, providing a promising solution to decarbonizing various industries and sectors.

What are Electrolyzers?

- Definition: Electrolyzers are devices that use electricity to split water (H₂O) into its constituent elements: hydrogen (H₂) and oxygen (O₂). This process is called electrolysis.

- Importance: Electrolyzers are key to producing "green hydrogen." This refers to hydrogen generated using renewable energy sources like solar or wind power, making it a carbon-free fuel.

How Electrolyzers Work

- Components: An electrolyzer consists of:

- Anode: The positively charged electrode where oxygen is produced.

- Cathode: The negatively charged electrode where hydrogen is produced.

- Electrolyte: A substance (usually a liquid solution or a polymer membrane) that conducts electricity and allows ions to move between the electrodes.

- Electrolysis Process:

- Water is fed into the electrolyzer.

- Electric current is passed through an electrode immersed in the electrolyte.

- At the anode, water molecules lose electrons and split into oxygen gas and positively charged hydrogen ions (protons).

- The hydrogen ions travel through the electrolyte to the cathode.

- At the cathode, the hydrogen ions gain electrons and form hydrogen gas.

Types of Electrolyzers

- Alkaline Electrolyzers: The most mature and commercially developed technology. They use a liquid alkaline solution as the electrolyte.

- Polymer Electrolyte Membrane (PEM) Electrolyzers: Use a solid polymer membrane as the electrolyte. They are more responsive to dynamic power sources like renewables.

- Solid Oxide Electrolyser (SOECs): Operate at high temperatures and can be more efficient but are still in earlier stages of development.

Uses of Green Hydrogen (Hydrogen produced through electrolysis)

- Energy Storage: Green hydrogen can store excess renewable energy for later use.

- Decarbonizing Industry: Green hydrogen can replace fossil fuels in hard-to-decarbonize industries like steel, cement, and chemical production.

- Transportation Fuel: Used in fuel cell vehicles for zero-emission transportation.

Benefits of Electrolysers:

- Production of green hydrogen, a clean and sustainable fuel.

- Reduction of greenhouse gas emissions compared to fossil fuels.

- Potential for widespread adoption across various industries, including transportation, energy storage, and industrial processes.

Challenges and Opportunities:

- Scaling up electrolyser manufacturing to meet increasing global demand.

- Reducing the cost of electrolysers to make green hydrogen more competitive.

- Developing efficient and environmentally sustainable methods for hydrogen storage and transportation.

The Future of Electrolysers:

Electrolyzers hold immense potential as a key technology in the future transition to clean energy. By using electrical power to produce green hydrogen, electrolyzers contribute to a more sustainable and environmentally conscious world.

Must Check: Best IAS Coaching In Delhi