- Courses

- GS Full Course 1 Year

- GS Full Course 2 Year

- GS Full Course 3 Year

- GS Full Course Till Selection

- Answer Alpha: Mains 2025 Mentorship

- MEP (Mains Enrichment Programme) Data, Facts

- Essay Target – 150+ Marks

- Online Program

- GS Recorded Course

- Polity

- Geography

- Economy

- Ancient, Medieval and Art & Culture AMAC

- Modern India, Post Independence & World History

- Environment

- Governance

- Science & Technology

- International Relations and Internal Security

- Disaster Management

- Ethics

- NCERT Current Affairs

- Indian Society and Social Issue

- NCERT- Science and Technology

- NCERT - Geography

- NCERT - Ancient History

- NCERT- World History

- NCERT Modern History

- CSAT

- 5 LAYERED ARJUNA Mentorship

- Public Administration Optional

- ABOUT US

- OUR TOPPERS

- TEST SERIES

- FREE STUDY MATERIAL

- VIDEOS

- CONTACT US

Scramjet Engine: A Breakthrough in Hypersonic Technology

Scramjet Engine: A Breakthrough in Hypersonic Technology

In January 2025, the Defence Research and Development Laboratory (DRDL), under the Defence Research and Development Organisation (DRDO), successfully conducted a 120-second ground test of an active-cooled scramjet combustor for the first time in India.

Key Highlights from the Test

- Indigenous Endothermic Fuel: DRDL, in collaboration with industry partners, developed an indigenous endothermic scramjet fuel.

- This fuel absorbs heat from its surroundings during a chemical reaction, improving the cooling process and easing ignition.

- Ceramic Thermal Barrier Coating (TBC): A state-of-the-art Ceramic TBC was developed jointly by DRDL and the Department of Science and Technology (DST).

- This coating can withstand extreme temperatures during hypersonic flight, with a thermal resistance high enough to operate beyond the melting point of steel.

|

Know the term

|

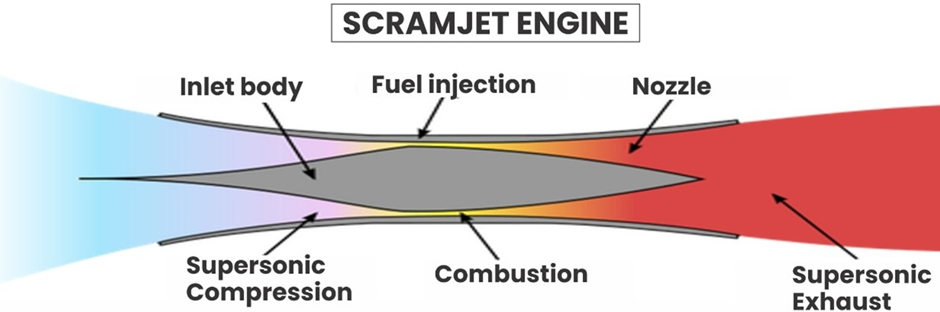

What is a Scramjet Engine?

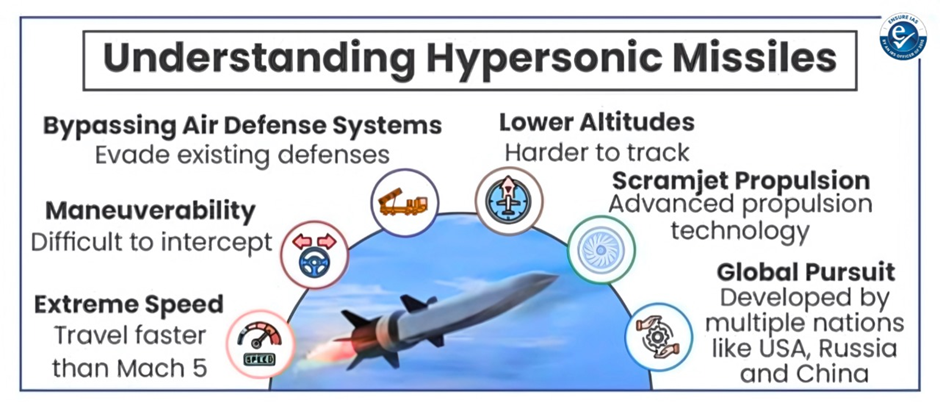

- A scramjet engine stands for Supersonic Combusting Ramjet. It is an advanced air-breathing propulsion system that allows efficient operation at hypersonic speeds (Mach 5 and above) and enables supersonic combustion.

- Scramjets are an improvement over traditional ramjets, which are simpler air-breathing engines.

- While ramjets use forward motion to compress air for combustion, scramjets take it a step further by sustaining combustion at supersonic speeds, making them suitable for hypersonic flight.

Working of a Scramjet Engine:

- Air Intake: The vehicle must already be moving at speeds greater than Mach 3 (supersonic) to generate the necessary air compression.

- Compression: The high speed of the vehicle compresses incoming air.

- Combustion: Fuel (usually hydrogen) is injected into the compressed air and ignited, maintaining supersonic airflow.

- Thrust Generation: The hot gases produced from combustion expand and generate thrust, propelling the vehicle forward at hypersonic speeds, in accordance with Newton's Third Law of Motion: For every action (force), there is an equal and opposite reaction.

Features of Scramjet Technology

- Flame Stabilization: The scramjet engine uses a technique to stabilize flames inside the combustor, even when airspeed exceeds 1.5 km/s, a process akin to "keeping a candle lit in a hurricane."

- Assisted Take-off: Scramjets cannot generate thrust at zero airspeed. Therefore, they require a rocket-assisted take-off to reach the supersonic speeds needed for scramjet operation.

Challenges in Scramjet Development

- High-Energy Fuels: Fuels that provide the necessary energy for sustained combustion.

- High Initial Costs: Significant financial investment required for development

- Integration Issues: Require a launch mechanism to reach operational speeds.

- Active Cooling Systems: Systems that maintain optimal temperatures during operation.

- Heat-Resistant Materials: Materials that can withstand extreme temperatures without degrading

Advantages of Scramjet Technology

- Efficiency: Scramjet engines are more fuel-efficient than traditional rocket engines. While rockets carry both fuel and oxidizer, scramjets rely on atmospheric oxygen for combustion, which reduces the need to carry large amounts of oxidizer.

- Cost Reduction in Space Missions: The reusable nature of jet engines will significantly reduce the cost of space exploration. Scramjet-powered rockets could carry heavier payloads, making space missions more cost-effective.

- Higher Speeds: Scramjets can achieve speeds beyond Mach 6, opening up possibilities for faster space access and hypersonic flight.

- Enhanced Deterrence: Scramjets are critical in the development of hypersonic missiles and reconnaissance aircraft, enhancing the strategic deterrence capabilities of nations.

Comparison between Scramjet and Ramjet engines:

|

Feature |

Scramjet Engine |

Ramjet Engine |

|

Speed Range |

Hypersonic (Mach 5 and above) |

Supersonic (Mach 3 to Mach 5) |

|

Combustion Type |

Supersonic combustion (combustion at supersonic speeds) |

Subsonic combustion (combustion at subsonic speeds) |

|

Air Intake |

Supersonic speeds (Mach 3+) |

Supersonic speeds (Mach 3+) |

|

Airflow in Combustor |

Supersonic |

Subsonic |

|

Efficiency |

More efficient (uses atmospheric oxygen) |

Less efficient (requires both fuel and oxidizer) |

|

Operational Altitude |

High altitudes (above 80 km) |

Medium altitudes (up to 45 km) |

|

Take-off |

Requires rocket assistance |

Requires rocket assistance |

|

Applications |

Hypersonic flight, space exploration, military missiles |

Supersonic aircraft, cruise missiles |

|

Development Status |

Experimental, under development for hypersonic missions |

Established and operational for supersonic flight |

|

Fuel |

Primarily hydrogen |

Jet fuel or kerosene and liquid oxygen |

India's Progress with Scramjet Engines

India has now joined an elite group of nations, including the USA, Russia, and China, that have successfully tested scramjet engines. This breakthrough positions India to leverage scramjet technology for defense and space applications, with the potential for hypersonic missiles, space exploration, and cost-effective satellite launches.

|

Also Read |

|

UPSC Foundation Course |

|

| UPSC Monthly Magazine | CSAT Foundation Course |